El panel de yeso sin papel es diferente del panel de yeso con revestimiento de papel., que necesita fuerza de unión desde el exterior durante el fraguado inicial de la lechada para que la lechada alcance la forma requerida después del proceso de formación. Por esta razón, Nuestra empresa ha desarrollado un nuevo tipo de máquina formadora con estructura de correa superior e inferior., y la correa inferior tiene un borde deflector que sobresale para evitar que la lechada corra hacia ambos lados durante el proceso de formación.. La polea de correa activa adopta rodillos de gran diámetro para aumentar el radio de curvatura de la correa y la vida útil de la correa.. La polea del cabezal de la correa de formación superior adopta un diseño elevable para satisfacer las necesidades de diferentes formas de tableros.. Y hace que la tela de la rejilla interna quede paralela y plana dentro del panel de yeso para garantizar la consistencia de toda la resistencia del panel.. Las correas superior e inferior están hechas de material nuevo y equipadas con un dispositivo de limpieza en una sección y un dispositivo de ajuste automático de múltiples secciones en la parte media para garantizar el espesor de la tabla.. Hace que los tableros terminados tengan la mejor resistencia a la flexión..

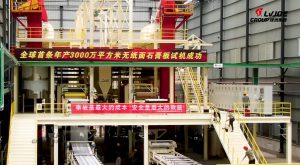

Línea de producción de paneles de yeso sin papel

Línea de producción de paneles de yeso sin papel

Línea de producción de paneles de yeso sin papel

Desarrollo de maquinaria Co., Ltd de Hebei Lvjoe

Desarrollo de maquinaria Co., Ltd de Hebei Lvjoe