The building gypsum powder is the main raw material with large consumption. The gypsum powder from the gypsum powder production line is stored in the gypsum powder silo which is outside the plant firstly, the silo is equipped with a discharger at the bottom to discharge the powder in the silo to the conveyor evenly, then the powder is conveyed to the intermediate silo in the dosing section, the intermediate silo plays the role of stabilizing the material, the powder in the intermediate silo is discharged evenly by the discharger at the bottom, and the powder is lifted by the bucket elevator to the overloading conveyor which is on top of the belt scale. There are two discharge openings. The first discharge opening is connected to the high-precision closed type rigid impeller feeder at the top of the belt scale, then it enters the high-precision electronic belt scale for continuous metering, and the measured powder is conveyed to the double screw mixing conveyor. The excess powder is returned to the intermediate silo through the second discharge opening to participate in the next cycle. This system is equipped with an excessive screw conveyor feeding and return screw system, which ensures the “constant pressure” state of the feeding part of the electronic scale and greatly improves the metering accuracy of this gypsum powder feeding system.

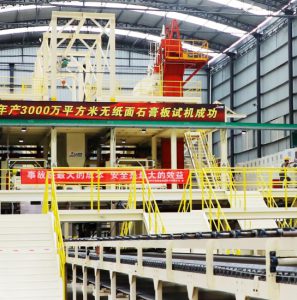

Linha de produção de placa de gesso sem papel

Desenvolvimento de máquinas Hebei Lvjoe Co., Ltd

Desenvolvimento de máquinas Hebei Lvjoe Co., Ltd