It consists of distributor, dryer, and board discharging machine. The dryer is divided into board feeding section, closed section, board discharging section, 등. The dryer heats the circulating air by heating thermal oil through heat exchanger by coal-fired boiler, and the heated top hot air is distributed to the plates on each layer of roller conveyor through the side air chamber. Uniform heating is realized and longitudinal airflow circulation is formed. The dryer is designed on the basis of the drying equipment of paper-faced gypsum board and modified by adjustment. It plays an important role in ensuring product quality and reducing production cost.

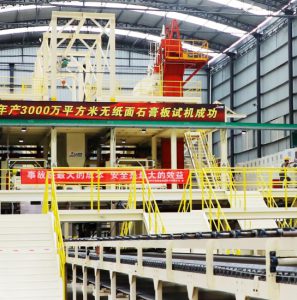

종이 없는 석고보드 생산 라인

허베이 Lvjoe 기계 개발 유한 회사

허베이 Lvjoe 기계 개발 유한 회사